Market Estimation & Definition

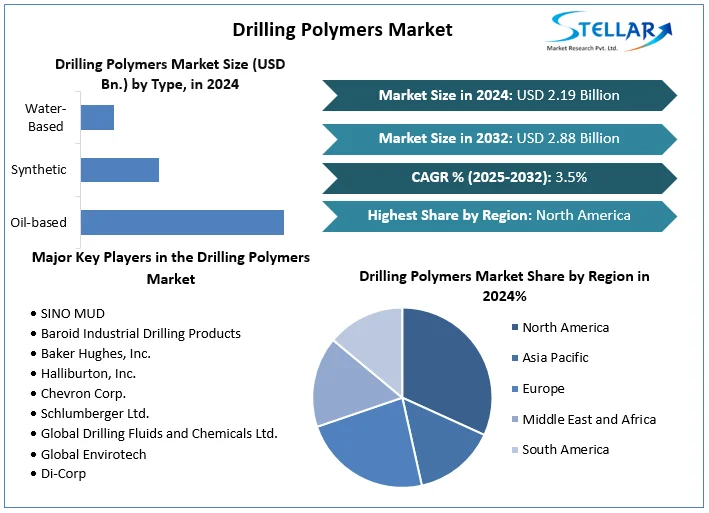

The Drilling Polymers Market refers to the segment of chemical additives—polymers—that are used in drilling fluids (muds) to enhance wellbore stability, cuttings transport, viscosity, and other performance parameters during drilling operations. According to Stellar Market Research, the market was valued at approximately USD 2.19 billion in 2024, and is projected to reach USD 2.88 billion by 2032, growing at a CAGR of 3.5%.

Request Free Sample Report:https://www.stellarmr.com/report/req_sample/Drilling-Polymers-Market/1477

Market Growth Drivers & Opportunity

Several key factors are driving growth in the drilling polymers market:

-

Increased Oil & Gas Exploration: As global energy demand rises, exploration and production (E&P) activities are expanding, pushing demand for high-performance drilling fluids.

-

Advanced Drilling Techniques: More complex drilling operations — such as deepwater, unconventional formations, fracking and horizontal wells — require polymers that deliver enhanced rheological properties.

-

Cost Efficiency & Operational Optimization: By improving fluid stability, reducing fluid loss, and helping transport drill cuttings, drilling polymers can reduce non-productive time and lower overall drilling costs.

-

Environmental & Regulatory Pressure: There is a growing shift toward water-based drilling fluids over oil-based ones due to ecological concerns, and drilling polymers compatible with water systems are gaining traction.

-

Diversification Across Industries: Beyond oil & gas, applications are expanding into mining and construction drilling, increasing the addressable market.

These factors create opportunity for polymer manufacturers to innovate, especially in environmentally friendly formulations or polymers tailored for challenging drilling scenarios.

What Lies Ahead: Emerging Trends Shaping the Future

Important trends forecast to shape the drilling polymers market include:

-

Bio-Based Polymers: Development of recyclable or bio-derived drilling polymers (e.g., from soy protein or cornstarch) is gaining momentum, driven by sustainability goals.

-

Higher Performance Synthetic Polymers: Next-gen synthetics are being engineered for better thermal stability, viscosity control, and fluid-loss reduction, especially in aggressive or deep wells.

-

Wider Use in Mining & Geothermal: As those sectors grow, demand for drilling polymers will increase in non-oil drilling applications, broadening market reach.

-

Digital Optimization: Integration of drilling operations with data analytics could push demand for polymers that support real-time fluid optimization and predictive maintenance.

-

Supply Chain & Raw Material Innovation: Fluctuating raw material costs (e.g., acrylamide) and the need for more sustainable sources are driving R&D into new polymer chemistries.

Challenges include R&D cost, regulatory burden for new polymer formulations, and supply chain risks.

Segmentation Analysis

Stellar segments the drilling polymers market across several dimensions:

-

By Type:

-

Oil-based polymers

-

Synthetic polymers

-

Water-based polymers (the most used, due to environmental compatibility)

-

-

By Drilling Technique:

-

DTH (Down-The-Hole) drills

-

Diamond drilling

-

Top hammer drilling

-

Reverse circulation drilling

-

Others

-

-

By Application:

-

Onshore drilling

-

Offshore drilling

-

-

By End-Use Industry:

-

Oil & Gas (largest)

-

Mining

-

Construction

-

Other drilling applications

-

-

By Region:

-

North America (largest share)

-

Europe

-

Asia-Pacific (fastest growth)

-

Middle East & Africa

-

South America

-

This segmentation helps stakeholders prioritize where to invest — for example, water-based synthetics for onshore drilling, or specialty polymers for mining.

Regional Insights

-

North America: Dominant in 2024, driven by strong U.S. exploration activity and advanced drilling infrastructure.

-

Asia-Pacific: Projected to grow rapidly (CAGR > 4%) as energy demand surges, especially in China and India, and as exploration expands into unconventional and deep reserves.

-

Europe: Growing emphasis on environmentally compatible drilling fluids is encouraging adoption of water-based and synthetic drilling polymers.

These regional insights suggest that while North America remains a cornerstone, APAC is the key growth frontier.

Commutator (User) Analysis

Key consumer segments (“commutators”) in this market include:

-

Oil & Gas Operators: Use drilling polymers to maintain drilling fluid consistency, stabilize wellbore, and optimize drilling efficiency.

-

Mining Companies: Rely on polymers in drilling for mineral exploration and extraction, where polymer performance helps improve penetration and reduce formation damage.

-

Construction Firms: For piling and foundation drilling, polymers help control fluid behavior and cuttings transport, improving drilling safety and cost.

-

Service Providers: Drilling fluid companies and chemical providers who formulate drilling fluids for E&P clients benefit from advanced polymers to differentiate their offering.

-

Challenges: Users face cost pressures, regulatory compliance, and pressure to adopt greener alternatives. Trust in polymer performance and consistency is vital.

Companies that can offer high-performance, cost-effective, and environmentally friendly polymer blends are likely to win trust and loyalty among these users.

Press-Release Conclusion

In summary, the Drilling Polymers Market is forecast to grow steadily from USD 2.19 billion in 2024 to USD 2.88 billion by 2032 (CAGR ~3.5%). This growth is underpinned by rising E&P activity, demand for efficient and stable drilling fluids, environmental trends favoring water-based polymers, and expansion into non-oil sectors such as mining and construction.

The future points to innovation: bio-based polymers, high-performance synthetics, and integration with digital drilling workflows are key themes. For polymer manufacturers, oilfield service companies, and drilling fluid providers, the opportunity lies in developing next-generation, eco-conscious solutions that meet both performance and sustainability needs.

Drilling polymers are evolving from basic additives to essential components of modern, efficient and responsible drilling — a critical lever for operational excellence in a fast-changing energy landscape.

About us

Phase 3,Navale IT Zone, S.No. 51/2A/2,

Office No. 202, 2nd floor,

Near, Navale Brg,Narhe,

Pune, Maharashtra 411041

sales@stellarmr.com