In many manufacturing and workshop settings, the high performance straight shank drill is favored for its balance, repeatability, and straightforward use. It supports efficient drilling operations, especially in small-to-medium batch production where accuracy and durability are required.

Unlike tapered shank drills, the straight variant is easier to align and center. This makes it particularly useful in general-purpose drilling where frequent tool changes are necessary. The standardized dimensions also reduce setup time and enable smoother tool management.

When drilling into metals, plastics, or composite materials, tool rigidity plays a major role in the quality of the outcome. A straight shank drill, especially when used in a properly clamped fixture, contributes to smoother finishes and improved dimensional control. This can be especially important when preparing parts for assembly or downstream processing.

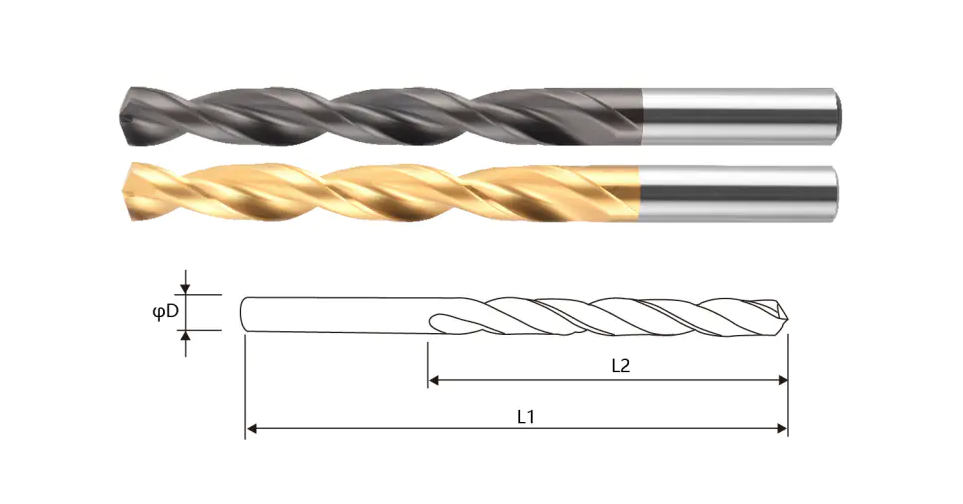

To handle different material types, manufacturers often provide coatings or surface treatments. A common example includes titanium-based layers that help minimize wear and heat buildup. These enhancements can make a significant difference during extended runs or tougher materials.

In addition to performance, the straight shank drill supports a practical workflow. Users can replace bits without recalibrating toolholders, assuming the same diameter is retained. This contributes to efficiency, especially in operations with varying tooling needs.

Maintaining the drill involves standard procedures: ensuring sharpness, cleaning flutes to avoid debris buildup, and storing tools to avoid moisture exposure. With basic upkeep, these tools can provide long-term service and steady performance.

To conclude, the high performance straight shank drill is a trusted component in many machining tasks. Its simplicity, paired with modern design improvements, makes it a go-to solution for technicians seeking a dependable drilling option that integrates well with existing equipment.