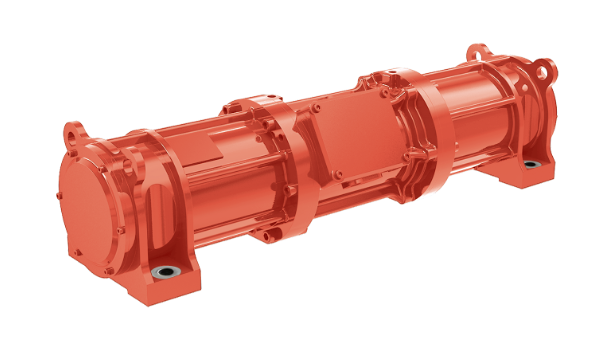

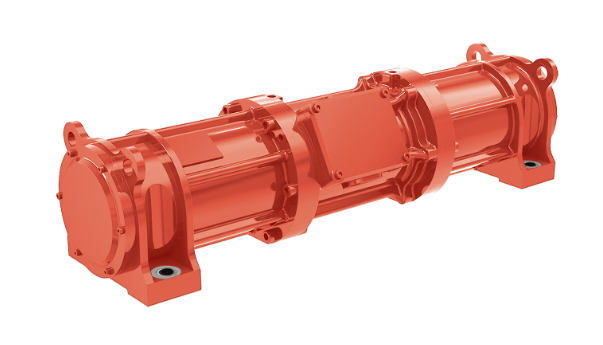

In recent years, the demand for explosion-proof technology has surged, particularly in industries such as oil and gas, mining, and chemical manufacturing. The need for reliable and safe equipment in hazardous environments has led to significant advancements in engineering and technology. Among these advancements, SUDA MOTOR three-stage long vibration motors have emerged as a promising solution.

Understanding Explosion-Proof Technology

Explosion-proof technology refers to the design and construction of equipment that can operate safely in environments where flammable gases, vapors, or dust may be present. The primary goal is to prevent ignition sources from causing explosions. This technology is critical in industries where volatile substances are handled, as even a small spark can lead to catastrophic consequences.

Key Features of Explosion-Proof Equipment

-

Robust Construction: Explosion-proof equipment is built with materials that can withstand high pressure and temperature, ensuring that any internal explosion does not escape to the external environment.

-

Sealing Mechanisms: Effective sealing prevents the ingress of flammable substances, reducing the risk of ignition.

-

Thermal Management: Proper heat dissipation mechanisms are essential to prevent overheating, which could ignite surrounding materials.

The Role of Vibration Motors in Industrial Applications

Vibration motors are widely used in various industrial applications, including material handling, compaction, and screening. Their ability to generate controlled vibrations makes them essential in processes that require the movement of bulk materials. However, in hazardous environments, the use of standard vibration motors poses significant risks.

Advantages of Three-Stage Long Vibration Motors

Three-stage long vibration motors are designed to provide enhanced performance and safety in explosive atmospheres. Their unique design offers several advantages:

-

Increased Efficiency: The three-stage design allows for better torque and speed control, resulting in improved efficiency in material handling processes.

-

Reduced Noise Levels: These motors operate more quietly than traditional models, which is beneficial in environments where noise reduction is a priority.

-

Enhanced Durability: The robust construction of three-stage long vibration motors ensures longevity, reducing the need for frequent replacements and maintenance.

Recent Advances in Explosion-Proof Technology

The development of three-stage long vibration motors has been accompanied by significant advancements in explosion-proof technology. Recent innovations include:

Improved Materials

The use of advanced materials, such as high-strength alloys and composites, has enhanced the durability and safety of explosion-proof equipment. These materials can withstand extreme conditions, making them ideal for use in hazardous environments.

Smart Technology Integration

The integration of smart technology into explosion-proof equipment has revolutionized the industry. Sensors and monitoring systems can provide real-time data on equipment performance, allowing for predictive maintenance and reducing the risk of failures.

Enhanced Certification Standards

As the demand for explosion-proof equipment grows, so do the certification standards. New regulations ensure that equipment meets stringent safety requirements, providing greater assurance to operators in hazardous environments.

Application Prospects of Three-Stage Long Vibration Motors

The application prospects for three-stage long vibration motors in explosion-proof technology are vast. Here are some key areas where these motors can make a significant impact:

Oil and Gas Industry

In the oil and gas sector, three-stage long vibration motors can be used in drilling operations, material handling, and equipment maintenance. Their explosion-proof design ensures safe operation in environments where flammable gases are present.

Mining Operations

Mining operations often involve the handling of explosive materials and dust. The use of three-stage long vibration motors can enhance safety and efficiency in processes such as ore sorting, material transportation, and compaction.

Chemical Manufacturing

In chemical manufacturing, the risk of explosions is a constant concern. Three-stage long vibration motors can be employed in mixing, blending, and conveying processes, providing a safe solution for handling hazardous materials.

Conclusion

The advancements in explosion-proof technology, particularly in the development of three-stage long vibration motors, represent a significant step forward in ensuring safety in hazardous environments. As industries continue to prioritize safety and efficiency, the application prospects for these motors are promising. With ongoing innovations and improvements, SUDA MOTOR three-stage long vibration motors are poised to play a crucial role in the future of explosion-proof technology.

https://www.sudazhendong.com/application-prospects-of-three-stage-long-vibration-motors.html