The process of cutting the raw material will be one that is both continuous and repeatable. This will take place as part of the manufacturing process.

It is going to have this procedure carried out on it. CNC machining is able to produce components that have a high level of complexity because the computer that controls and operates the machine throughout the entirety of the manufacturing process gives it the ability to do so.

In 1949, John Parsons invented a numerical control device that was adaptable and flexible enough to be utilized in a wide variety of settings and situations. In order to guarantee that a research project that had been commissioned by the Air Force would be successfully completed, the concept of numerical control, also known as NC and abbreviated as NC, was conceived. The Massachusetts Institute of Technology, also known as MIT, played the role of host institution for this particular research endeavor, and it served as the institution's home base. In addition to that, as a consequence of this, the manufacturing of blades for helicopters would be an option that could be pursued.

By the year 1952, Richard Kegg had already begun working with the other MIT alumni with whom he had graduated. The efforts of everyone who participated in the manufacturing process resulted in the successful creation of a milling machine.

Between the years 1940 and 1950, punched tape was utilized as one of the tools that were utilized in the machining process. When the 1960s and 1970s rolled around, digital technologies were already on the market, which made it possible to automate the manufacturing process. This was a game-changer for the manufacturing industry.

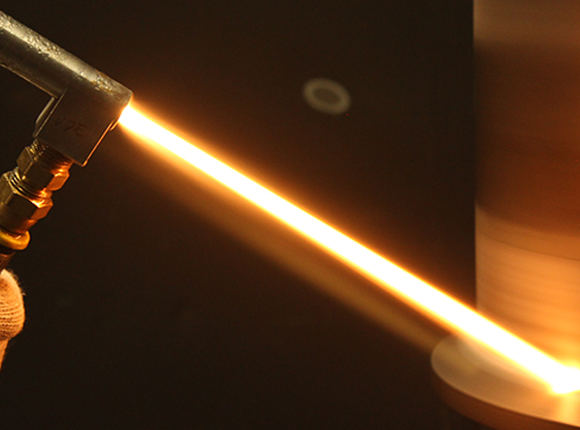

Machining carried out on a machine that is controlled numerically by a computer. CNC Machines, which are operated by means of computer numerical control, are now widely utilized across the entirety of the manufacturing industry. This method is also known as the Computer Numerical Control (CNC) Machining Process. A computer controls the production process, which enables multiple operations to be carried out concurrently on a single part. This increases efficiency and reduces waste. The same plan, which will function as the foundation for each and every procedure, will serve as the point of departure for all of them. An operation that is going to be carried out will be one that is automated and will make use of high-quality cutting tools in order to remove the material. It is possible to manufacture along a number of different axes on a component at the same time if you use this particular method of machining. Because it has a table that can move on its own and rotate with the part that is being cut, a computer numerically controlled machine, also known as a CNC, is able to ensure that the cutting process will be extremely accurate. Because of this, the final result of each and every individual product will be highly predictable, and it will produce results that cannot be surpassed by any other results.

In addition, the results it produces will produce results that cannot be surpassed by any other results.

What are the benefits of utilizing a computer numerically controlled (CNC) machine to carry out machining tasks?

The following are some of the advantages that come with using a CNC machine for machining:

Exquisite exactitude and precision

One hundred percent effective despite the breakneck speed at which it movesMakes possible the use of a wide variety of distinct kinds of materials

1) An Unrivaled Level of Preciseness and Accuracy Across the Board in Every Aspect

1) An Unrivaled Level of Preciseness and Accuracy Across the Board in Every Aspect

Because we have access to sophisticated CNC machines, we are able to manufacture products that come with intricate designs in a way that is both efficient and effective.

The computer numerical control (CNC) machinery that is used in the manufacturing of components is programmed to follow the instructions that are delivered by a computer so that the components can be manufactured. When the idea of numerical control, also known as NC, was first developed for the machining process, inaccuracies were frequently made on the machinery that was manually operated. This is what led to the development of the NC concept. In earlier eras, it would have been impossible to accomplish such a task.

In light of this, what exactly do we mean when we talk about accuracy, precision, and tolerance when talking about a machined part? To put it another way, accuracy is defined as the degree to which a measurement comes close to meeting the particular requirements outlined for the part. On the other hand, precision can be defined as the capability of a measurement assessment to repeatedly and continuously machine the exact same specifications and design. This is referred to as "machining repeatability."In this particular application, the term "tolerance" refers to the maximum permissible amount of deviation that must be adhered to in the proportions and measurements of that component. To put it another way, tolerance is synonymous with the amount of wiggle room that must be provided. The minimum tolerance standards that are generally required from a variety of different industries are routinely and to an extremely high degree surpassed by our machine shop. This is done in a consistent manner.

02) Not only very effective but also very prompt in taking action when necessary. In order to ensure that the manufacturing procedure was carried out in an effective manner, it was necessary for an operator to manually switch between the various cutting tools that were used throughout the production process. This was done to ensure that the manufacturing procedure was not interrupted. In the end, the decision as to which cutting tools were going to be used was made based on the strategy that was going to be utilized during the process of cutting. Not only that, but it does a poor job of carrying out the function it was intended to in the first place.

The current iteration of the CNC Machining Process makes use of a rotating table that is able to hold and make use of a wide variety of different kinds of tools. This table also rotates at a high rate of speed. As an immediate and direct consequence of this, a CNC machine will be able to perform cutting operations in a prompt and effective manner.

03) Able to Accommodate a Vast Assortment of Materials

There is a wide selection of materials available to choose from when it comes to the manufacturing process that is carried out using a CNC machine. In addition to this ability, CNC machinery has the capability of producing a very wide range of distinct products.

Compositions of components that are neither ferrous nor extraordinary:

AluminumCopper Bronze Brasstitanium, Teflon, stainless steel, and titanium all together. Machinable plastics include materials such as aluminum, copper, bronze, brass, titanium, stainless steel, and teflon. Other examples include bronze and brass.

Delrin Noryl Peek PVC UHMW