Plastic cup mould technology serves numerous market sectors with specialized requirements. In the food service industry, plastic cup mould designs produce disposable drink cups for beverages of various sizes. These plastic cup mould configurations must meet food safety standards and create products with consistent wall thickness for reliable performance. The hospitality sector utilizes plastic cup mould technology to manufacture reusable cups for hotels and resorts, often requiring more durable construction and aesthetic appeal than disposable versions.

The variety of products created using plastic cup mould technology demonstrates its adaptability. Beyond simple drinking vessels, plastic cup mould designs can produce measuring cups for kitchen use, specimen cups for medical applications, and specialty containers for industrial products. Each application demands specific considerations in the plastic cup mould design, such as material compatibility, dimensional accuracy, and structural requirements. The flexibility of plastic cup mould engineering allows manufacturers to respond to diverse market needs with appropriate product solutions.

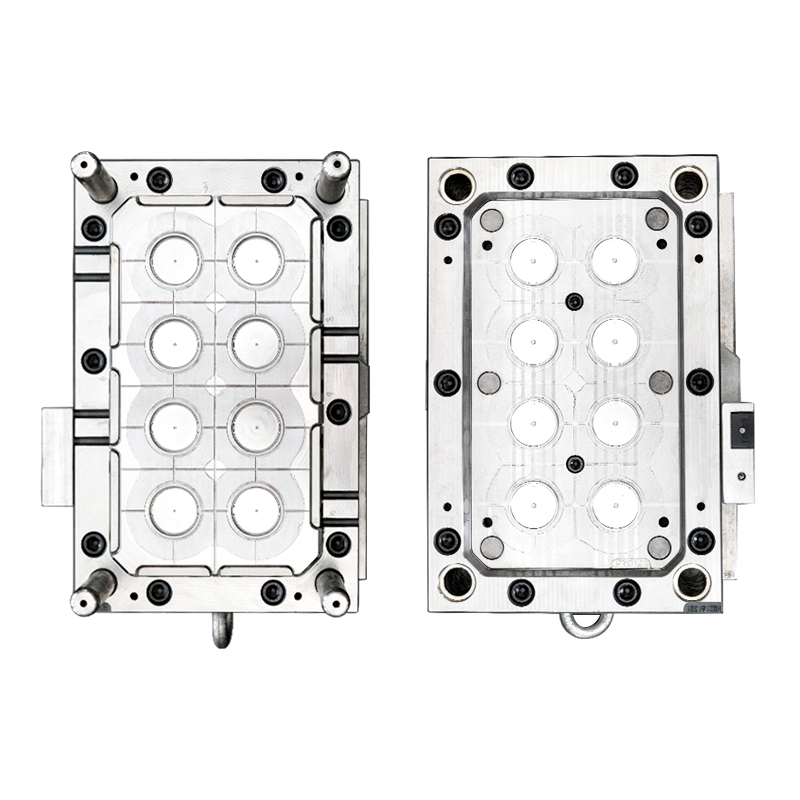

Innovations in plastic cup mould technology continue to evolve with industry trends. Environmental considerations have led to plastic cup mould designs compatible with biodegradable materials and recycled plastics. Advanced plastic cup mould systems now incorporate hot runner technology that reduces material waste by eliminating conventional sprues and runners. Some modern plastic cup mould configurations include in-mold labeling capabilities that apply decorative or informational labels during the forming process, adding efficiency to production lines.

The economic aspects of plastic cup mould utilization impact manufacturing decisions. The initial investment in a high-quality plastic cup mould is balanced against long-term production efficiency and product consistency. Manufacturers consider factors like plastic cup mould longevity, maintenance requirements, and production speed when selecting equipment. The versatility of plastic cup mould systems allows for quick changeovers between different cup designs, supporting just-in-time manufacturing approaches. As consumer preferences and material technologies continue to develop, plastic cup mould engineering adapts to create products that meet changing market demands while maintaining manufacturing efficiency.