The Li-Ion battery electrode coating market has experienced significant growth due to the increasing global demand for electric vehicles (EVs), energy storage systems, and portable electronic devices. The performance of lithium-ion batteries heavily depends on the quality and efficiency of electrode coatings, making the market highly sensitive to several influencing factors. This article explores the key aspects driving and shaping the growth trajectory of the Li-Ion battery electrode coating market.

Technological Advancements and Innovation

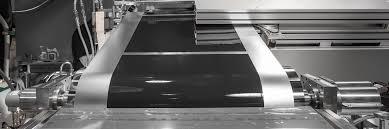

One of the most crucial factors impacting the market is the rapid pace of technological innovation. Manufacturers are continuously investing in research and development to improve electrode coatings’ conductivity, durability, and energy density. Advanced coating materials, such as nanostructured and conductive polymer coatings, enhance battery performance and extend lifecycle, making them attractive for high-end applications in EVs and grid storage. Furthermore, automation in coating processes and precision techniques like slot-die and doctor-blade coating ensures uniformity and consistency, which reduces manufacturing defects and improves battery reliability.

Rising Demand for Electric Vehicles

The increasing adoption of EVs globally is a primary growth driver for the Li-Ion battery electrode coating market. Governments across North America, Europe, and Asia-Pacific are implementing stringent regulations to reduce carbon emissions, promoting EV production and sales. Lithium-ion batteries are the preferred choice for EV manufacturers due to their high energy density and longer life cycles. Consequently, this demand exerts direct pressure on electrode coating suppliers to deliver high-performance, scalable, and cost-effective solutions.

Raw Material Availability and Pricing

Raw materials such as lithium, cobalt, nickel, and graphite are fundamental to the production of high-quality electrode coatings. Fluctuations in the availability and price of these materials significantly affect market dynamics. For instance, geopolitical tensions or mining restrictions in key producing countries can disrupt supply chains, leading to increased costs. Companies are increasingly exploring alternative materials or sustainable sourcing strategies to mitigate these risks and maintain consistent production levels.

Environmental Regulations and Sustainability Concerns

Environmental compliance and sustainability considerations are gaining prominence in the Li-Ion battery electrode coating market. Governments are enforcing strict regulations on chemical usage, waste management, and carbon footprint reduction in battery manufacturing. Companies are investing in eco-friendly coatings, solvent-free formulations, and recycling initiatives to minimize environmental impact. These efforts not only ensure regulatory compliance but also appeal to environmentally conscious consumers, further driving market growth.

Manufacturing Costs and Scalability

Manufacturing costs and scalability of electrode coating processes are key factors influencing market competitiveness. High-precision coating techniques require substantial capital investment, and the cost of advanced materials can be prohibitive. Companies must optimize production processes to balance performance with cost efficiency. Economies of scale, strategic partnerships, and technological improvements are critical to achieving competitive pricing and expanding production capacity to meet growing demand.

Market Competition and Strategic Collaborations

The Li-Ion battery electrode coating market is characterized by intense competition among key players, including chemical manufacturers, battery producers, and specialized coating solution providers. Strategic collaborations, mergers, and joint ventures help companies access cutting-edge technology, raw materials, and new markets. Moreover, partnerships with EV manufacturers and energy storage companies can provide long-term contracts and predictable revenue streams, boosting market stability.

Impact of Global Energy Transition

The shift towards renewable energy sources and decarbonization strategies is indirectly influencing the electrode coating market. Lithium-ion batteries play a critical role in storing solar and wind energy, creating additional demand for efficient and durable electrode coatings. As renewable energy projects expand worldwide, the need for high-performance energy storage solutions will drive innovation and market adoption, supporting long-term growth prospects.

Consumer Expectations and Product Performance

Consumer demand for high-capacity, fast-charging, and long-lasting batteries is shaping electrode coating development. End-users in electronics, automotive, and industrial applications expect consistent performance under various operating conditions. Manufacturers are focusing on improving thermal stability, minimizing capacity loss, and enhancing charge-discharge efficiency of coatings to meet these expectations, ensuring product competitiveness and market relevance.

Conclusion

The Li-Ion battery electrode coating market is influenced by a combination of technological, environmental, and economic factors. Innovations in coating materials, rising EV adoption, raw material dynamics, sustainability mandates, and global energy transitions collectively shape market growth. Companies that strategically align their R&D, manufacturing, and sustainability initiatives with these influencing factors are likely to secure a competitive advantage in this rapidly evolving sector. As demand for high-performance lithium-ion batteries continues to rise, the electrode coating market is poised for robust expansion, driven by innovation, efficiency, and sustainability.