Tension Controller – Precision and Efficiency in Every Production Process

In the competitive landscape of modern manufacturing, achieving optimal tension control is essential to ensuring high-quality products and efficient production lines. Whether you are producing textiles, films, wires, or other flexible materials, improper tension control can lead to defects, inefficiencies, and material wastage. At CBB Machine, we offer a state-of-the-art Tension Controller that provides real-time monitoring and adjustment, ensuring that your production process runs smoothly and efficiently. This technology is designed to meet the needs of various industries, delivering superior performance in material handling and improving the overall quality of your products.

Key Features and Advantages of the Tension Controller

Real-Time Tension Monitoring and Adjustment

One of the most important features of our Tension Controller is its ability to monitor tension levels in real time. As the production process moves forward, the system continuously checks the tension on materials and makes immediate adjustments when needed. This real-time functionality ensures that tension remains consistent across all materials, whether they are films, fabrics, papers, or wires. Maintaining proper tension throughout the manufacturing process prevents issues such as material breakage, misalignment, or uneven processing, which can compromise the quality of the final product.

Precision Control for High-Quality Output

Precision is paramount in many manufacturing processes, especially when working with sensitive materials. Whether you are in the textile, printing, or packaging industry, even slight fluctuations in tension can result in defects that are costly and time-consuming to fix. The Tension Controller ensures that tension is controlled with high accuracy, preventing these issues and ensuring that your production line consistently delivers high-quality results. By maintaining precise tension, manufacturers can avoid common problems such as wrinkling, stretching, or uneven coatings, all of which can impact the final product’s appearance and functionality.

Improved Efficiency and Reduced Downtime

The Tension Controller plays a crucial role in improving the efficiency of your production line. By maintaining consistent tension, the system minimizes the risk of interruptions due to material-related issues, reducing downtime and allowing for faster production cycles. With fewer stops for adjustments, your production process becomes more streamlined, which leads to a higher throughput and improved productivity. This increase in efficiency allows manufacturers to produce more units in less time, ultimately reducing operational costs and improving overall profitability.

Wide Compatibility Across Multiple Applications

The Tension Controller is designed to be flexible and versatile, offering compatibility with a wide range of machinery used in various industries. Whether you're running unwinding machines, slitting machines, printing presses, or other types of equipment, the Tension Controller can be easily integrated into your existing production line. It is suitable for use in industries such as textiles, packaging, wire manufacturing, and printing, providing a universal solution for precise tension control. The system is adaptable to various materials, including films, metals, papers, and textiles, ensuring that it can meet the specific demands of your production environment.

User-Friendly Interface for Easy Operation

Despite its advanced capabilities, the Tension Controller is designed to be user-friendly and simple to operate. The system features an intuitive digital interface that allows operators to quickly set up and adjust tension settings as needed. The clear display shows real-time data, giving operators the information they need to make quick adjustments without having to navigate complex menus or settings. This ease of use ensures that even operators with minimal technical training can effectively manage tension control and monitor production performance.

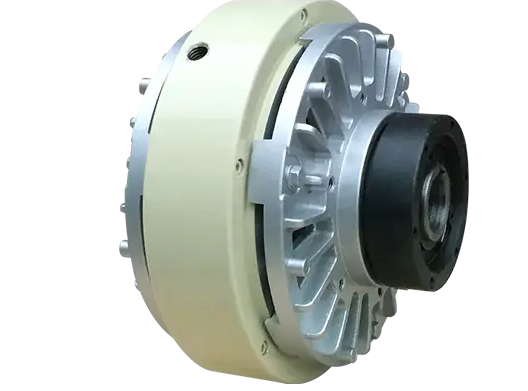

Durable and Reliable Design

Built for the rigors of industrial environments, the Tension Controller is constructed with high-quality materials that ensure its durability and long lifespan. This robust design means that the system can operate continuously in demanding manufacturing conditions without the need for frequent maintenance or repairs. By investing in a durable solution, businesses can reduce operational disruptions and ensure that their production lines remain up and running, even during long shifts or high-demand periods.

Cost Savings Through Waste Reduction

One of the most significant benefits of using the Tension Controller is its ability to reduce material waste. Improper tension often leads to product defects, which in turn leads to wasted raw materials and increased scrap. By ensuring that tension is always within the optimal range, the Tension Controller helps prevent such issues, reducing material wastage and ultimately lowering production costs. With better tension control, manufacturers can maximize their material usage, reduce waste, and improve their bottom line by producing high-quality products at a lower cost.

Applications Across Multiple Industries

The Tension Controller from CBB Machine is suitable for a wide range of industries and applications. Some of the key areas where this technology is highly beneficial include:

Textile Manufacturing: Controls tension during weaving, knitting, and fabric finishing processes, ensuring uniformity and preventing material breakage.

Printing: Maintains consistent tension during printing operations, improving print quality and preventing misalignment or smudging.

Packaging: Ensures optimal tension when unwinding and rewinding packaging materials, preventing material distortion or damage.

Wire Manufacturing: Regulates the tension in wire production, ensuring smooth winding and preventing tangling or snapping.

Applications in Various Industries

The Tension Controller from CBB Machine is ideal for use in industries that require precise tension control. Some of the key sectors that can benefit from this technology include:https://www. cbbmachine .com/about/

Conclusion

The CBB Machine Tension Controller is an essential tool for any manufacturing process that involves material handling and tension control. With its real-time monitoring, precise tension adjustment, and ability to integrate with a wide range of equipment, this system provides a reliable and efficient solution for enhancing production quality and productivity. Whether you’re in the textile, packaging, printing, or wire manufacturing industries, the Tension Controller will help you improve operational efficiency, reduce material waste, and produce high-quality products consistently. Investing in the Tension Controller will not only streamline your manufacturing processes but also drive long-term cost savings and boost profitability.